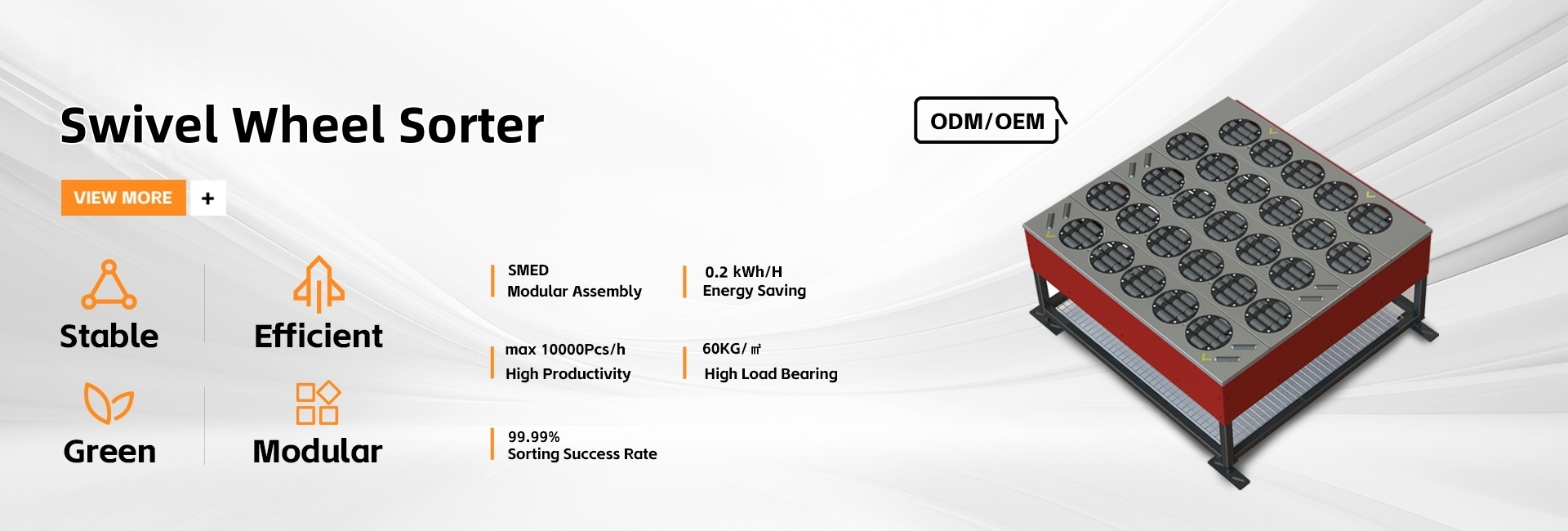

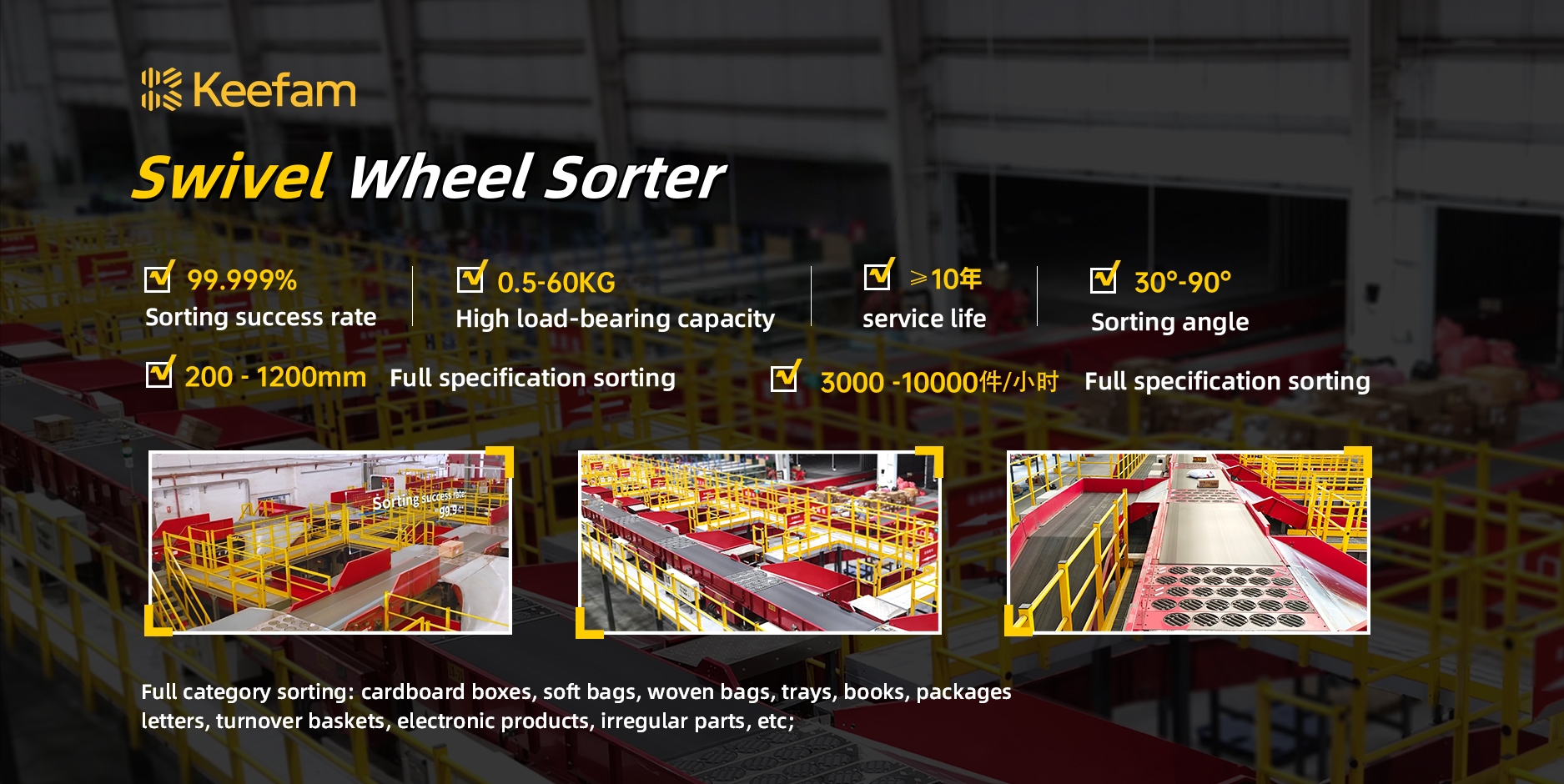

Swivel Wheel Sorter

Swivel Wheel Sorter is a multi-wheel type sorting device, for heavy parts...

Swivel Wheel Sorter is a multi-wheel type sorting device, for heavy parts...

Ultra High Speed Multi-wheel Sorter

Swivel Wheel Sorter is a multi-wheel type sorting device, for heavy parts...

Swivel Wheel Sorter is a multi-wheel type sorting machine.

It is suitable for sorting applications of packaging types such as heavy items, woven bags, flexible packaging, uneven items, and cartons.

Modular design and assembly can be applied to large, medium and small different application sites.

According to the actual situation of the project, to provide you with exclusive customized sorting solutions and the best project services.

Sorting systems are crucial in industries where large volumes of items need to be processed quickly and accurately.

Such as in logistics, e-commerce, manufacturing, and warehousing.

Swing Wheel Sorter Features

1. High sorting success rate

99.99%

2. Energy saving and power saving

0.2 kWh of electricity per hour, saving 60% energy consumption compared with the same type of models

3. High load-bearing capacity

Standard load-bearing capacity is 60KG/㎡, no pressure on heavy goods supply

4. High sorting efficiency

3000-10000 pieces/hour, flexible selection according to production capacity requirements

5. Full specification sorting

200mm-1200mm

6. Long service life

≥10 years

7. Modular design

Plug and play, quick replacement in 10 minutes

8. Supports sorting types

Cartons, soft bags, woven bags, pallets, books, parcels, letters, turnover baskets, electronic products, special-shaped parts, etc.

Balance Wheel Sorting Machine Technical Parameters

| Modular Swivel Wheel Sorter Product Parameters | |||||||||

| Model | Capacity | Goods Category | Load | Operational Speed | operational Noise | Specification(mm) | Line Width(mm) | Cargo Size mm | Cargo Interval(mm) |

| (pieces/hour) | (kg) | ||||||||

| Swivel Wheel Sorter of medium speed | 800-4000 | All categories | 0.2-60 | 0.8m-1.5/s | ≤65dB | 700x860x700 | 800 | 160*100-600*600 | 450 |

| 920x1060x700 | 1000 | 160*100-1000*800 | 450 | ||||||

| 1200x1260x700 | 1200 | 160*100-1200*800 | 450 | ||||||

| Intelligent sorting machine of high speed | 4000-6000 | All categories | 0.2-60 | 0.8m-2.2/s | ≤65dB | 700x860x700 | 800 | 160*100-600*600 | 450 |

| 920x1060x700 | 1000 | 160*100-1000*800 | 450 | ||||||

| 1200x1260x700 | 1200 | 160*100-1200*800 | 450 | ||||||

| Swivel Wheel Sorter of ultra high-speed | 7000 | Standard container goods | 0.2-35 | 150m/min | ≤65dB | 760x760x600 | 800 | 200*200-800*600 | 660 |

| 8000 | 150m/min | 520x520x600 | 600 | 200*200-600*400 | 540 | ||||

| 760x760x600 | 800 | 200*200-800*600 | 540 | ||||||

| 10000 | 180m/min | 520x520x600 | 600 | 200*200-600*400 | 480 | ||||

| 760x760x600 | 800 | 200*200-800*600 | 480 | ||||||

1. Side sorting Scenario :

The logistics companyuses 1260mmX950mmX1200mm specifi-cation products for unilateral sorting of heavy carton goods onthe assembly line.

2. Parallel use Scenario :

The express company uses 1260mmX1200mmX700mm products andmulti-wire parallel arrangement to sort the goods on the assembly lineon both sides

3. Left-right sorting Scenario :

The storage company uses 1060mmX920X600mm specificationproducts to double-sort the drinks and beverages on theassembly line.

4. Series use Scenario :

The express company uses 1260mmX1200mmX700mm specificationproducts, multiple units are arranged in series, and all categories ofgoods are sorted on the assembly line.

5. Food Scenario :

A food company uses 1260mmX1200mmX700mm specificationproducts to double-sort fresh goods on the assembly line.

6. Electronic product Scenario:

A technology company uses1260mmX1200mmX600mmproducts to sort display goods on the assembly line on bothsides.

Whole Process Quality Inspection

The company has ISO9001 international quality system certification, strict testing process, from raw material warehousing, production process control to finished products out of the warehouse, each link is strictly quality control, to ensure that product quality meets national standards and customer requirements; Professional inspection team, team members have rich industry experience and professional skills, can accurately judge product quality problems, and put forward improvement measures in time; The company pays attention to the construction and improvement of quality management system, through continuous improvement and innovation, improve product quality level and production efficiency, to meet the increasing needs of customers.